RAY Egelhof - High heat resistant Oil/Gas combination burners “HTK-NA” - series

RAY Egelhof - High heat resistant Oil/Gas combination burners “HTK-NA” - series are used at all kinds of firing kilns, furnaces and post combustion chambers and are suitable for separate or parallel firing of liquid fuels such as LFO and Green fuels as well as all technical combustible gases, biogases, hydrogen, LPG and process gases.

RAY Egelhof - High heat resistant Oil/Gas combination burners “HTK-NA” - series are available in a capacity range from 120 kW (409 MBTU) - 5.400 kW (18,428 MBTU).

For more information, please get in contact with us - our team will be happy to support you!

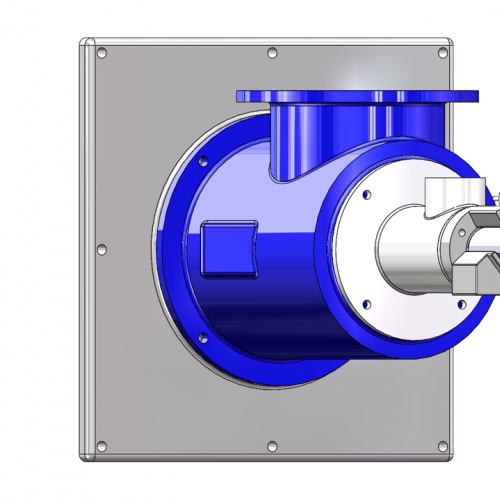

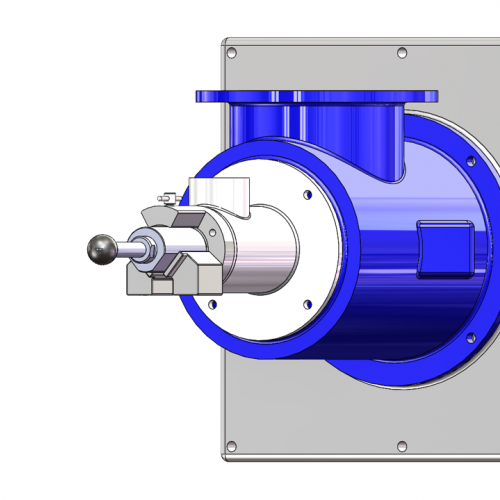

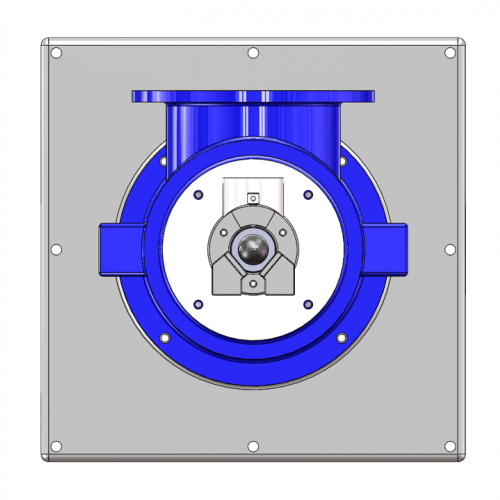

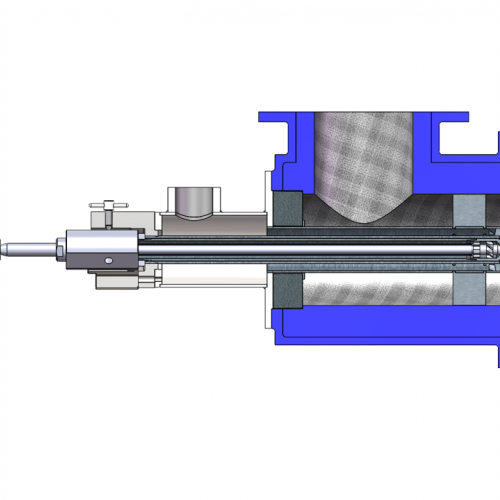

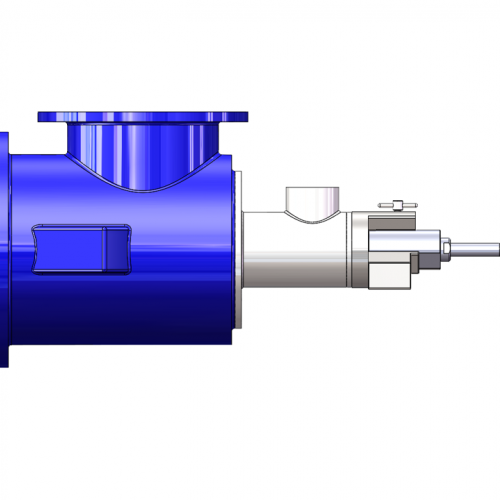

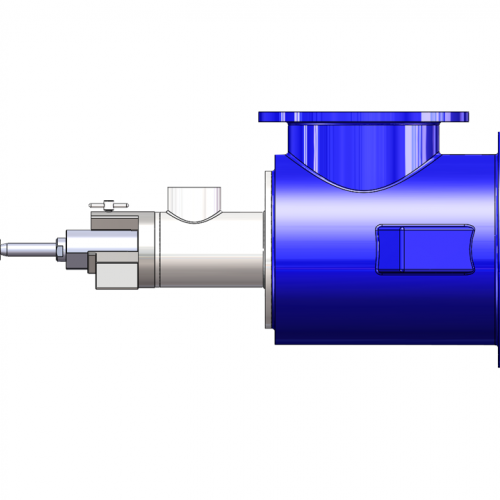

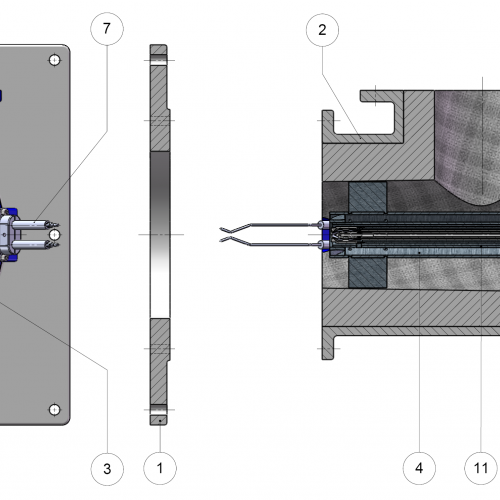

Design of the burner

You will find the matching picture in the slider on the right!

| 1. Burner plate | 2. Burner housing |

| 3. Gas connection flange | 4. Gas pipe with air baffles |

| 5. Insulating insert | 6. Quick-release clamp |

| 7. Ignition electrodes | 8. Tommy screw |

| 9. Nozzle block | 10. Flame sensor bracket |

| 11. Nozzle block protection tube |

Operating range

Burner operating range in relation to combustion air temperature

| Burner type | 20°C | 100°C | 200°C | 300°C | 400°C | 500°C | 600°C | 700°C | 800°C | Weight burner with burner plate |

| 100% | 75% | 65% | 55% | 45% | 40% | 35% | 30% | 27% | ||

|

kW MBTU |

kW MBTU |

kW MBTU |

kW MBTU |

kW MBTU |

kW MBTU |

kW MBTU |

kW MBTU |

kW MBTU |

kg | |

| HTK-NA 40 |

120 409 |

94 321 |

74 252 |

61 208 |

52 177 |

45 154 |

40 136 |

36 123 |

33 113 |

ca. 37 |

| HTK-NA 50 |

180 614 |

141 481 |

112 382 |

92 314 |

78 266 |

68 232 |

60 205 |

54 184 |

49 167 |

ca. 45 |

| HTK-NA 65 |

300 1,024 |

236 805 |

186 635 |

153 522 |

131 447 |

114 389 |

101 345 |

90 307 |

82 280 |

ca. 53 |

| HTK-NA 80 |

480 1,638 |

377 1,286 |

297 1,013 |

246 839 |

209 713 |

182 621 |

161 549 |

145 495 |

131 447 |

ca. 73 |

| HTK-NA 100 |

780 2,661 |

613 2,092 |

483 1,648 |

399 1,361 |

340 1,160 |

296 1,010 |

262 894 |

235 802 |

213 727 |

ca. 105 |

| HTK-NA 125 |

1.200 4,094 |

943 3,218 |

743 2,535 |

614 2,095 |

523 1,784 |

455 1,552 |

403 1,375 |

361 1,232 |

328 1,119 |

ca. 122 |

| HTK-NA 150 |

1.560 5,323 |

1.226 4,183 |

967 3,299 |

798 2,723 |

679 2,317 |

591 2,016 |

524 1,788 |

470 1,604 |

426 1,454 |

ca. 150 |

| HTK-NA 200 |

3.000 10,236 |

2.357 8,042 |

1.859 6,343 |

1.534 5,234 |

1.306 4,456 |

1.137 3,879 |

1.007 3,436 |

904 3,084 |

820 2,798 |

ca. 201 |

| HTK-NA 250 |

4.200 14,330 |

3.300 11,260 |

2.602 8,878 |

2.148 7,329 |

1.829 6,241 |

1.592 5,432 |

1.410 4,811 |

1.265 4,316 |

1.147 3,914 |

ca. 268 |

| HTK-NA 300 |

5.400 18,425 |

4.242 14,474 |

3.346 11,417 |

2.762 9,424 |

2.352 8,025 |

2.047 6,984 |

1.813 6,186 |

1.627 5,551 |

1.475 5,033 |

ca. 323 |

Note: Burner operating range refers to standard furnace and combustion air conditions.